Scope optimisation for Turnarounds

Development and implementation of Minimum Intervention Strategy for Inspection (MISI) has resulted in cost reductions for shutdown related inspection work of up to 50% . The MISI concept was launched at the API Inspection Summit in Galveston USA in January 2015 and has been very successfully applied in many installations since.

MISI-Consultancy can deliver a review of your existing maintenance & inspection strategy with a focus on data quality, the status of Risk Based Maintenance analysis and the specification of an optimised maintenance & inspection scope.

Although developed for the Oil and Gas industry the concept and principles can easily be applied for other industries as well.

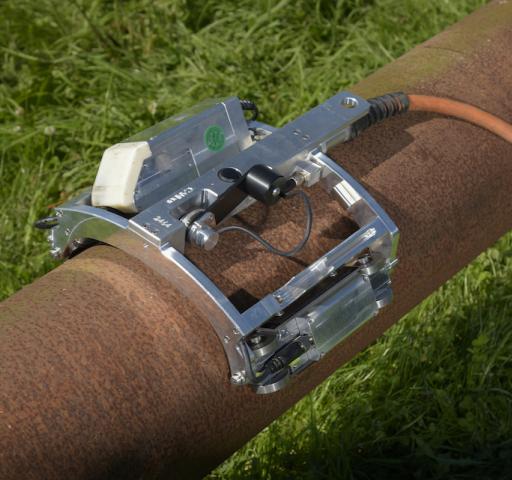

MISI-Consultancy can execute these activities for you and guide the implementation. We collaborate with reputable companies in non-destructive testing, robotic applications and inspection data analytics.

- Belgium

- Germany

- Netherlands

- Norway

- United Kingdom